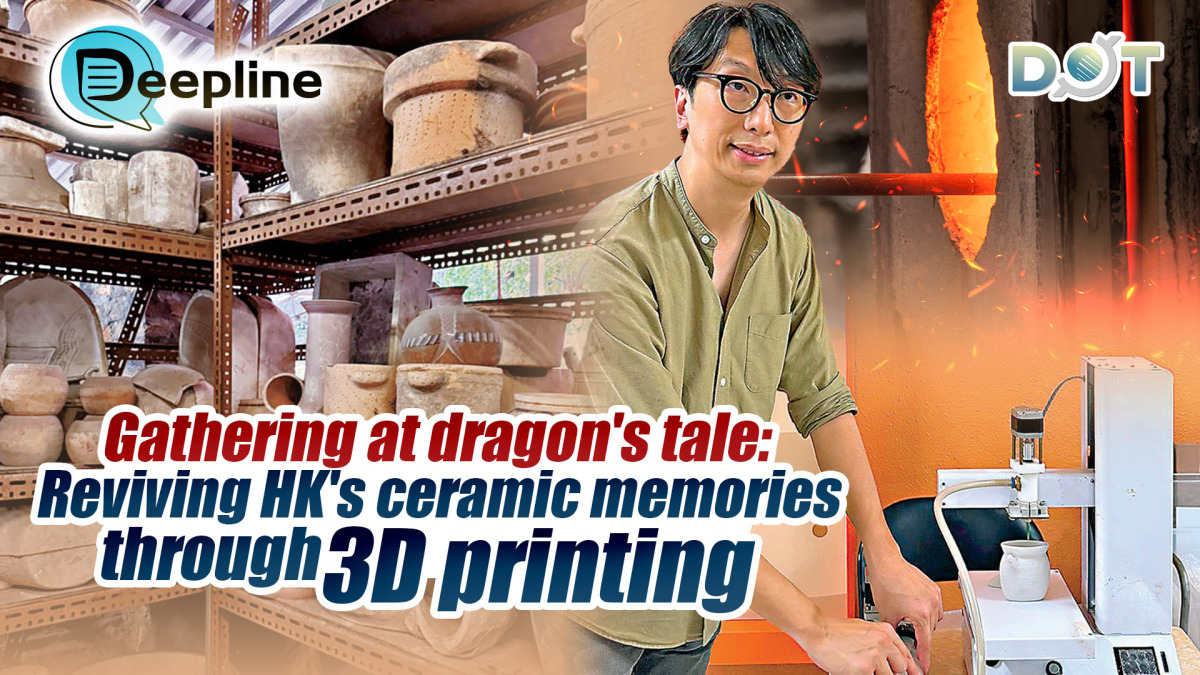

If the dragon kiln could express itself, the eighty-year-old Castle Peak Dragon Kiln, now located in the Hin Fat Estate public housing complex in Tuen Mun, would undoubtedly be unable to conceal its welcome and excitement toward the new friends who have been visiting frequently lately. In May of this year, Ray Chan, a lecturer at the Hong Kong Baptist University Academy of Visual Arts and a ceramic artist, completed his new contemporary ceramic art installation in the public space of Hin Fat Estate, Tuen Mun.

This art installation was co-created by over a hundred participants, including community members from Tuen Mun, ceramic enthusiasts, and students from the Academy of Visual Arts. It encapsulates the public's shared memories of the Castle Peak Dragon Kiln and their personal life experiences.

Since 2023, Chan has led workshops where he personally guided and instructed participants to sketch designs of ceramic items from their memories. These designs were then brought to life using a combination of 3D printing technology and traditional wood-firing techniques, aiming to reproduce dragon kiln products while transforming public memories into tangible objects.

Revive memories

As a ceramic artist with over twenty years of dedication to the craft, Chan's research extends beyond the techniques themselves. In his exploration of combining 3D computer printing technology with ceramic creation, he discovered that this process could also be used to recreate Hong Kong citizens' memories of the Castle Peak Dragon Kiln.

The Castle Peak Dragon Kiln is currently the only fully preserved dragon kiln in Hong Kong. Built in the 1940s, it played a significant role in firing daily ceramic products during its heyday, including items such as drainage pipes, flower pots, clay pots, incense burners, and ceramic statues—products familiar to many Hong Kong citizens. It also witnessed the prosperous development of Hong Kong's light industry from the 1950s to the 1970s.

To recreate the familiar utensils from public memory, Chan first transformed the public's submitted sketches into digital designs. He then used 3D computer printing technology and soft clay to turn these 2D images into physical objects. He adopted the firing methods originally used at the Castle Peak Dragon Kiln, relying on traditional wood firing to complete the entire process instead of the commonly used electricity or gas today.

Ceramic works fired at high temperatures with wood often exhibit a faint brownish-green hue—a result of the interplay between wood, flame, oxygen, and clay minerals. This adds a natural charm to the 3D-printed pieces.

When viewing the ceramic art installation on-site, the public may notice that it differs significantly from conventional ceramic art presentations. As the viewing distance and angle change, different facets of the installation become visible. Chan explained that many visitors, upon first entering the public space for the exhibition, might mistake the wall-hung installation for a painting from afar. Upon closer inspection, they may think it is a conventional ceramic work. Only when they move even closer do they realize that it is a ceramic piece created through resized 3D printing.

Next to this large-scale art installation are Chan's reproductions of traditional dragon kiln products, while on the other side are works based on designs submitted by the public. These seemingly ordinary pots and pans are arranged in a lifelike order against a wall adorned with light-colored murals, evoking the feeling of a past-era living room or kitchen. In an interview, Chan mentioned that the installation revolves around "life" itself rather than merely replicating the dragon kiln. Thus, visitors will encounter a variety of utensils commonly found in everyday life scenarios.

A small 3D printer is also on display at the site to explain the process and principles of 3D ceramic printing to the public. "A small piece can be printed in about 10 minutes, while larger works may take several hours," said Chan.

A "living museum"

A dragon kiln is a traditional wood-fired kiln used for pottery, reaching temperatures of up to 1,300 degrees Celsius during firing, with flames roaring like a reclining fire dragon. In earlier workshops led by Chan, many ceramic enthusiasts and members of the public had the opportunity to visit the Castle Peak Dragon Kiln up close for the first time, guided by the second-generation kiln master, Leung, to witness the kiln's original form.

Although it has been "extinguished" for forty years, the Castle Peak Dragon Kiln still retains its grandeur. Beneath a simple metal shed, the 17-meter-long kiln lies along a slope. Entering through small arched doors reveals a long, corridor-like chamber. Squatting inside and looking upward, one can see rows of fist-sized holes along the arched ceiling. During firing, segments of wood were fed through these holes to raise the temperature inside the chamber. Throughout the tour, visitors can see finished products from the kiln's past, intuitively sensing the traces of time on these ceramic pieces.

Leung has innovatively created simple panels displaying the materials and proportions used in ceramic making to facilitate public participation and experience. The preservation of the kiln in its original site and form, along with public close-up visits, has turned the Castle Peak Dragon Kiln into a "living museum," keeping the flame of dragon kiln culture alive.

(Source: Wen Wei Po; Journalist: Chen Yi; English Editor: Darius)

Related News:

Deepline | Illuminating history: Laser technology reveals ancient Peruvian tattoos

Deepline | Closing loophole: HK's new strategy to prevent fake local labor shortages

Comment